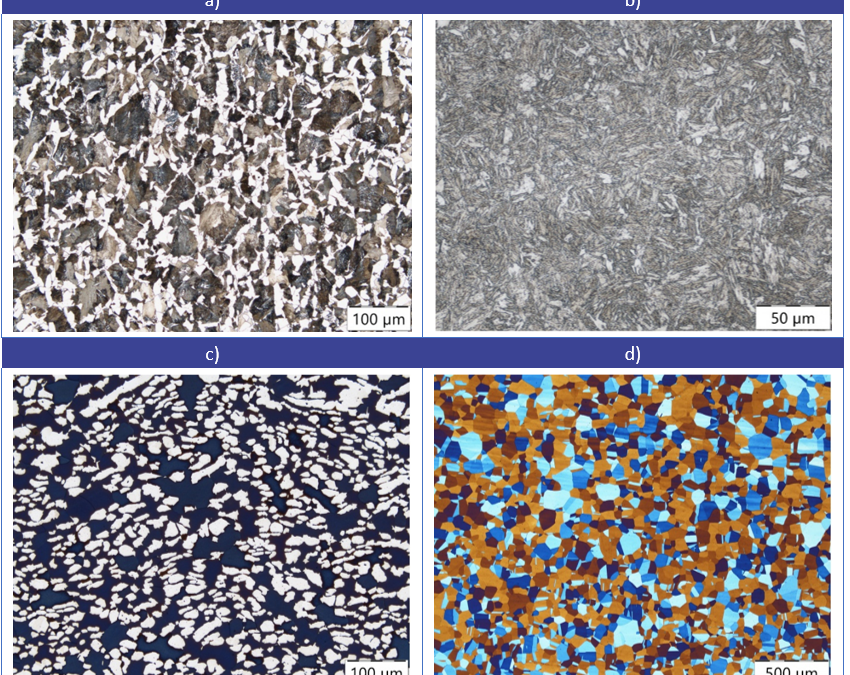

In the course of work package WP4 of the Hystories project, a material characterization of selected steels was carried out by the Chair of General and Analytical Chemistry, at the Montanuniversitaet Leoben. For the further experiments, it is essentially to obtain a chemical analysis, to evaluate the mechanical properties and to characterize the microstructure of all materials. Following materials have been investigated, K55 ferritic-pearlitic steel with an Ulimate Tensile Strength (UTS) of 682 MPa, L80 tempered martensitic steel (UTS = 636 MPa), L80 martensitic steel (UTS = 1606 MPa), P110 tempered martensitic steel (UTS = 958 MPa), 20MnV5 ferritic-pearlitic steel (UTS = 517 MPa), welded nickel-based Alloy 625, 2205 Duplex austentic-ferritic steel (UTS = 654 MPa) and 316L austentic stainless steel (UTS = 469 MPa). There is a fine microstructure for all investigated materials (grain size < 50 µm), only the 316L shows the usual coarser grain size, a few important microstructures are shown in the figure below.

Microstructure of a) ferritic-pearlitic K55, b) quenched & tempered L80, c) austeitic-ferritic Duplex stainless steel 2205, d) austenitic stainless steel 316L.

Full report is available here.